Welcome

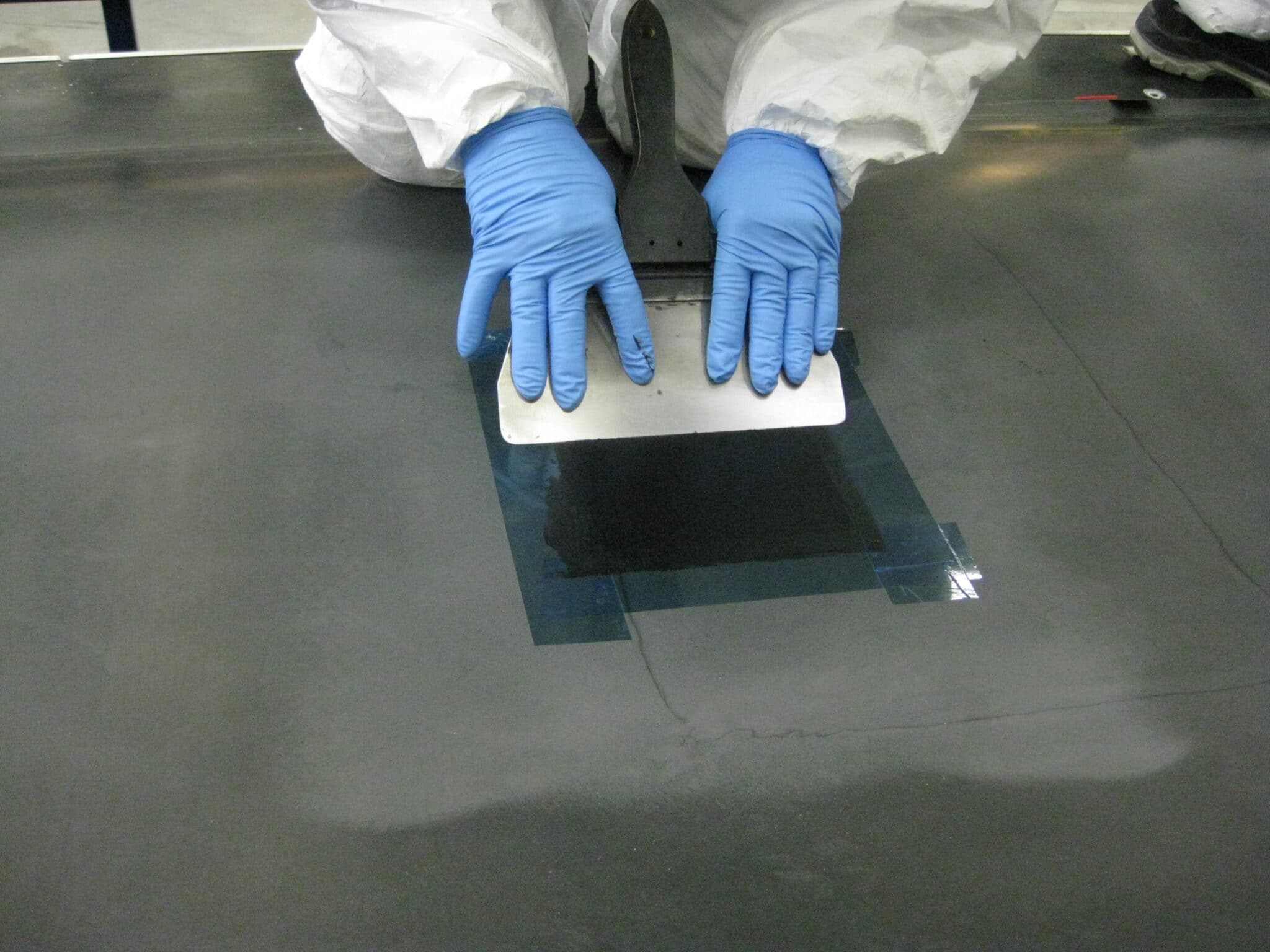

Installation, Repair, Sanding, Surface Treatment, Our Own Tools

MouldProtec secures our clients an external team of highly skilled technicians within Mould Maintenance to Wind Turbine Blade manufacturing plants. The moulds performance and surface quality have a critical and costly impact in the annual delivery performance of blades to end-users. Sudden repairs or productions stop should be avoided and limited. Such standards require specified knowledge and expertise in mould maintenance, which can be a missing resource locally. Refurbishments often take place in holiday seasons, where it’s difficult and expensive to acquire enough internal personnel. That’s why MouldProtec is here to support You!

About us

Let us take care of your moulds! Your moulds performance are essential for reaching a tight production schedule. Let us help you make sure your moulds perform as they should. We offer highly experienced workers, we use our own tools and equipment, and we can help you in every stage of mould maintenance, building, or installation.

We make repairs, sanding, cleaning, sealing and apply release treatment. Your moulds will be back in production to agreed time – while your own workers can have their holidays and focus 100% on their key competence – producing Wind blades!

Our Mission

Ensure technical mould preparation standards

for wind blade production environments

Worldwide in combination with efficient

tools and working methods securing

time-savings and optimal performance!

Our Vision

To be the prefered external outsourcing

partner and consultant within technical

and practical execution and supervision in

mould preparation processing for Wind

Turbine Blade manufacturing!

Contact us

MouldProtec ApS

Strandkanten 4, 6950 Ringkøbing, Denmark

Mail: info@mouldprotec.com

MouldProtec – Consulting Dept.

Technical Responsible, Jan Pedersen

Cell: +45 2368 2523

Skype: japed.

Mail: japed@mouldprotec.com